- Can hold approximately 3-4 times per metre, the rock mass of a normal Friction Bolt

- One pass bolting solution

- Compatible with Jumbo installing mesh

- Offers a genuine alternative to a resin bolt

- Easier to install than a resin bolt

Split Set Mining Systems mission was to develop a system to install pre-grouted Friction Bolts using the existing equipment and methodology of regular Friction Bolts. Without compromising ease of installation, compatibility with mesh and shotcrete, overall productivity and increasing the level of safety provided.

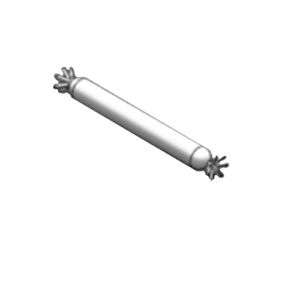

How it works; The thick grout is pre-placed into the bolt via the use of a wet cement sausage, inserted into the bolt before the installation of the bole in the hole. The bolt is then installed ‘as normal’.

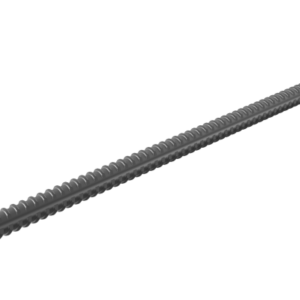

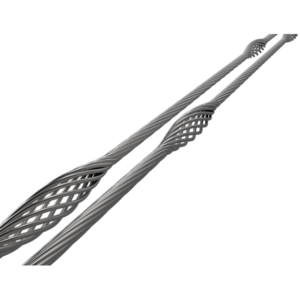

Performance can be greatly improved by grouting the inside of the bolt using a thick strong grout. This occurs because Split Sets conform to the shape of the borehole in which they are installed and the grout once set locks the shape dimensions of the Split Set in the Hole. A typical 45mm borehole varies 1mm along its length.

In order to remove the grouted bolt from the hole either the grout, the steel, the rock or some combination of theses three needs to fail.